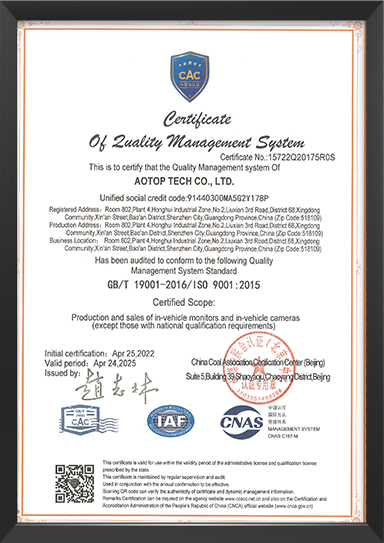

quality management (QM)

Our factory is TS16949 and ISO certified, which means we follow strict quality management systems to ensure the highest level of quality control in the production of our products.

Experience Reliable Quality with Our TS16949 and ISO Compliant Production Cycle

We take pride in our manufacturing system that ensures a dust-free environment to maintain the highest quality standards for our vehicle camera and monitor systems. We use only excellent raw materials to ensure that our products last a lifetime. Our efficient production cycle is TS16949 and ISO certified, which guarantees that our processes meet international standards of quality management. Our highly trained employees work collaboratively across departments to ensure that our manufacturing process is streamlined and efficient. Additionally, all our products undergo thorough inspections and various tests to ensure that they meet our quality standards and exceed our customers’ expectations.

Our Trustworthy Raw Material Suppliers

SONY&SHARP

Worldwide Market Leader In Camera Lenses.(CMOS/CCD)

M-STAR/Allwinner

The best Automotive display driver chip manufacturers.

hannstar

The best LCD Panel supplier for our car monitor

nextchip

The best Camera DSP Supplier

Our Product Testing Protocol

Our rigorous quality control process for our vehicle camera and monitor system includes a total of 20 different tests to ensure the highest level of performance and reliability. Here are some of the tests we perform:

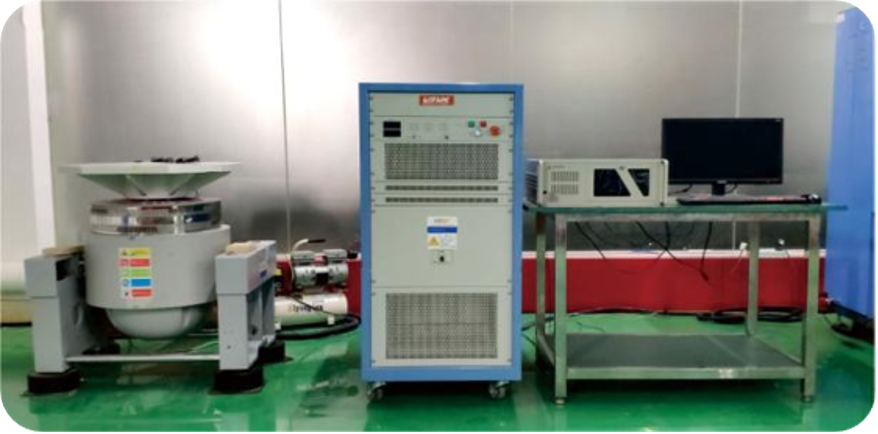

professional of test equipments

Our company’s product test center is designed to meet the highest standards of quality and precision. The center is housed in a spacious environment, complete with an industrial-grade anti-static floor and a 6S on-site management method, ensuring a clean and organized workspace. All test equipment is placed scientifically and rationally to facilitate efficient testing procedures.

Our test center is fully equipped with a wide range of experimental equipment, allowing us to test all aspects of our vehicle camera and monitor systems, from spare parts to finished products. We have comprehensive testing capabilities, ensuring that our products meet the most rigorous quality standards.

Our testing procedures include functional testing, durability testing, environmental testing, and more. We use advanced testing equipment and software to ensure that our products are reliable and perform well under all conditions. All products are thoroughly inspected and tested before being shipped to our customers, ensuring that they meet the highest quality standards.

Signal shielding test

Our signal shielding laboratory is equipped with various devices such as a GPS signal generator, navigation signal simulator, and audio analyzer to recreate scenarios where signals are interfered with or absent. This allows us to thoroughly test the performance and reliability of our products in real-world situations and ensure they can withstand various forms of signal interference.

uv aging test

We use a UV aging testing machine to simulate the effects of strong UV light on our products in an outdoor environment. This allows us to test and evaluate the durability and lifespan of our products under extreme conditions, ensuring that they can withstand prolonged exposure to sunlight without deteriorating or malfunctioning. By subjecting our products to rigorous testing, we can guarantee their quality and performance even in harsh environments.

electrothermal constant-temperature dry box

We use an electrothermal constant-temperature dry box and constant temperature humidity chamber to simulate various environmental conditions, such as high temperature, humidity, low temperature, and extreme heat and moisture. These tests help us ensure that our products are durable and can withstand different weather conditions. By subjecting our products to these extreme conditions, we can identify any weaknesses and make necessary improvements to ensure that they meet our high-quality standards.

salt spray tester

The salt spray tester is utilized to simulate harsh environmental conditions, including acid rain and other corrosive elements. This allows us to test the durability and corrosion resistance of our vehicle camera and monitor system, ensuring that it can withstand extreme weather conditions and maintain its performance over time.

shaking table, impact test

We use specialized equipment, such as the shaking table, impact test bed, and intersection detection, to simulate scenarios where a vehicle may encounter an uneven road or collision. These tests are conducted to ensure that our vehicle camera and monitor systems can withstand the impact and vibration and continue to function properly. By subjecting our products to these rigorous tests, we can guarantee their durability and reliability even under harsh conditions.

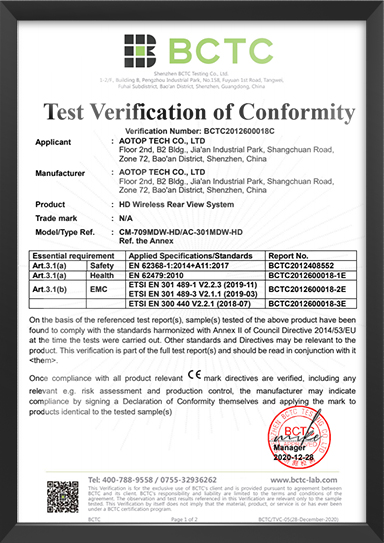

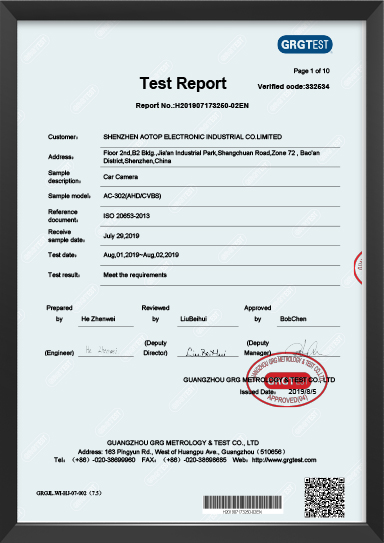

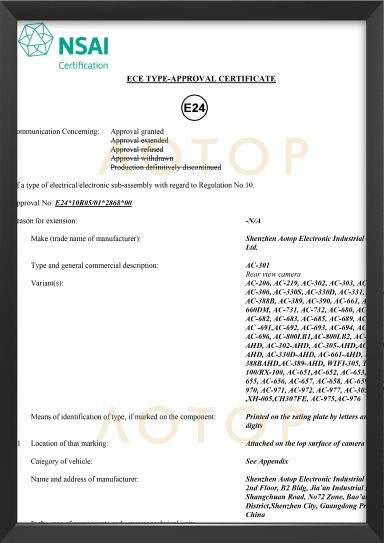

certifications

Our company has a 17-year of experience in producing the best Vehicle Camera and Monitor Systems. These certifications are a testament to the fact that we only provide quality.

Ask for an Instant Quote For Your Upcoming Projects.

All inquiries will be replied to within 12 hours or sooner.